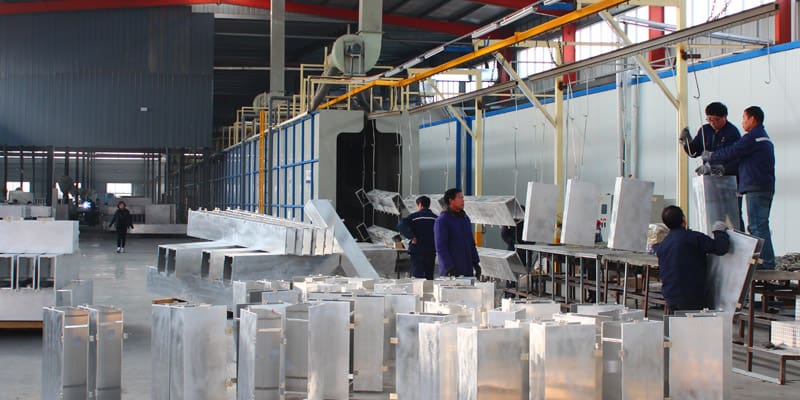

Aluminum sheet/coil/circle, PE/PVDF coated aluminum sheets, powder coating aluminum panel cladding high quality manufacture

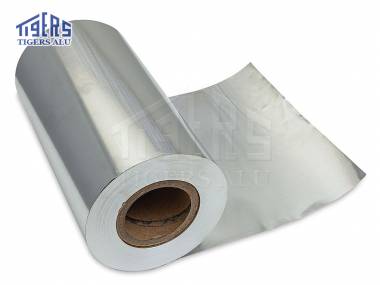

Aluminum Coil & Sheet

Tigers industry manufactures 1000, 3000, 5000, 6000, 8000 series alloy mill finish aluminum sheet and coil which can be processed into aluminum rounds, checker plate, diamond plate and cut to size.

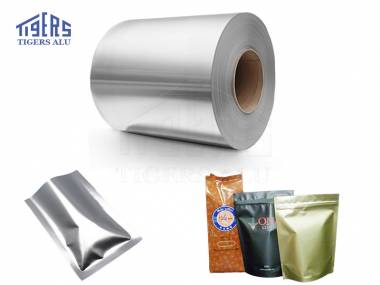

Aluminum Foil

We manufacture and supply large rolls of aluminum foil such as household foil, pharmaceutical foil,flexible packaging foil,container foil, etc. with a thickness of 0.005-0.2mm, at reasonable price.

Painted Aluminum Coil & Sheet

Tigers industry supplies coated aluminium coil and sheet with PVDF, PE and powder coating coatings. The coating thickness is 5 to 40 μm , powder coating can be coated more than 100 μm or requested.