How is 4×8 aluminum sheet produced?

The production process of 4×8 aluminum sheet

Simply put, the production of aluminum sheet needs to go through the production process of melting aluminum ingots, rolling into aluminum coils, annealing, and cutting, and the finished aluminum sheet needs to be packaged and then transported to customers.

Hot rolled aluminum sheet

The difference between 4×8 aluminum sheet and other aluminum sheets is that the size of the sheet is 4 feet x 8 feet when it is cut.

Cutting into 4×8 aluminum sheet plate

The cutting of 4ft × 8ft aluminum sheet plate can be done by various methods, such as sawing, shearing or CNC engraving machine or laser machine. We use CNC equipment for cutting, which can control the size better and reduce the error when producing, and there is no burr after cutting, and the edges of the aluminum sheet can also be rounded.

Aluminum sheet plate for decoration

A variety of aluminum alloy grades can be cut to 4ft × 8ft.

Commonly used alloys are:

- 1050 aluminum sheet plate

- 1060 alloy aluminum sheet

- 1100 alloy aluminum sheet

- 3003 aluminum sheet

- 3004 alloy aluminum sheet

- 3105 aluminum sheet

- 5052 aluminum sheet plate

- 5754 aluminum sheet

- 6061 alloy aluminum plate

- 6082 aluminum plate

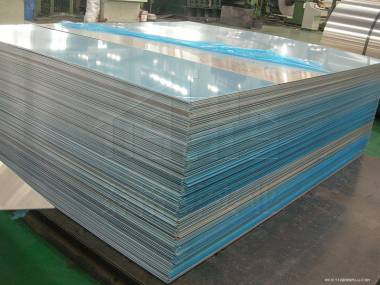

Aluminum sheet can be covered with PVC film on the surface or paper sandwiched between two aluminum sheets as needed when cutting, which can better protect the surface of aluminum sheet from damage and prevent oxidation.

Packaging of 4×8 aluminum sheet

After cutting, the aluminum plate will be reasonably divided according to the weight, placed neatly, completely wrapped with waterproof and moisture-proof PVC film outside, and a sufficient amount of moisture-proof agent will be added to prevent the oxidation of the aluminum sheet plate.

Then wrapped with rigid kraft paper to prevent the aluminum plate from being injured.

Finally, steel straps are applied for reinforcement.

Aluminum sheet plate and aluminum coil stock

Tigers aluminum can also supply 4×8 aluminum sheets in fumigated wooden boxes.

We are a manufacturer and stockist of aluminum alloy sheets and coils in China and stock 4×8 aluminum sheets in common alloy grades.