Henan Tigers Industry Co., Ltd. is a large-scale manufacturer of 0.32 painted aluminum coilin Henan. It uses high-quality aluminum alloy as the material. The products are processed and produced in strict accordance with national standards. The quality is different from ordinary aluminum and galvanized 0.32 painted aluminum coil, the coated layer is made of high-quality polyester fluorocarbon (PVDF), PE, powder coating, and can be customized to the width, thickness, color, pattern, and pattern as customer’s requirment.

We strictly control quality of products, so that shipped products per ton fulfill the national standard . Factory direct sales, low wholesale prices. We have a professional sales team to quickly calculate the quotation for you, and provide the price and information of 0.32 painted aluminum coilon that day, 0.32 painted aluminum coilof Tigers brand has agents and distributors in the five major regions of China, and exports to more than 80 countries around the world .

white 0.32 painted aluminum coil

0.32 painted aluminum coil simplely divided into:surface coated paint, polyester (PE) coated aluminum coil and fluorocarbon (PVDF) coated aluminum coil; epoxy roller coated aluminum coil. Of course, there are two other situations, one situations is that one side coated with PVDF and the other side coated with PE; the other situations is that both sides coated with PVDF.

Fluorocarbon coatings are polyvinylidene fluoride resins, mainly referring to vinylidene fluoride homopolymers or copolymers of vinylidene fluoride and other small amounts of vinylidene fluoride monomers.

In the chemical structure of the fluoric acid-based material, a fluorine/carbon bond is used.

The stability and firmness of the chemical structure make the physical properties of fluorocarbon coatings different from ordinary coatings.

In addition to abrasion resistance and excellent impact resistance in terms of mechanical properties, the color-coated aluminum plate also has long-term fading resistance and ultraviolet resistance, especially in severe weather and environments.

After baking at high temperature to form a film, the molecular structure of the coating is dense and has ultra-strong weather resistance.

Fluorocarbon coatings can be divided into traditional fluorocarbon coatings and nano-fluorocarbon coatings according to their film-forming structure on the surface.

ceiling 1mm white coated aluminum coil

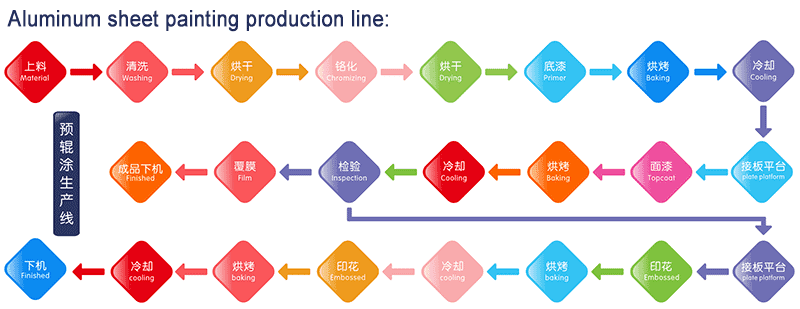

Production process of 0.32 painted aluminum coil

Aluminum sheet pre-roll coating process

Tigers paints solid color, wooden grain, brushed, marble grain, chameleon etc thick sheet painting production line.

Multi-layer painting process

Multilayer spraying process with three spraying(referred to as three sprays), spray bottom paint, topcoat and hood varnish and two spraying (primer, topcoat).</>

Coating thickness: It can be divided into single coating (4μm-20 μm); double coating (25μm-28 μm); 3 coating (35μm-38μm).

0.32 painted aluminum coil produced by Tigers is used for internationally advanced new decorative materials.

The pattern is high-grade and gorgeous, the color and texture are double real, the pattern is firm and wear-resistant, does not contain formaldehyde, and is non-toxic and harmful.

After decoration, there is no need to worry about the peculiar smell of paint and glue and physical damage. High quality, it is the material of choice for high-end architectural decoration.

Advantages of 0.32 painted aluminum coil

The main features of 0.32 painted aluminum coil are:

- Good temperature resistance, the melting point of aluminum is 660℃, and it is difficult to reach the melting point of aluminum in normal circumstances.

- Environmentally friendly, not easy to change color. Use chromium-free treatment solution for operation; roller coating contains active chemical molecules that can promote the formation of a protective layer on the surface of the material. Active chemical molecules are stable, easy to recycle, and meet environmental protection requirements.

- Corrosion resistance, because of the dense oxide film on the surface, it has strong adhesion, oxidation resistance, acid and alkali resistance, corrosion resistance, attenuation resistance, and UV radiation resistance.

- The color is uniform and durable, even and delicate, soft and gorgeous, avoiding the individual color difference phenomenon of traditional spraying. No matter how big the ceiling is, the color is consistent and permanent.

- Rigid and rigid combination, high strength of the board surface. Rigid-flexible combination, can be cut, split, curved, constant pressure, drilled, connected, fixed, blanking forming at will

camouflage pattern aluminum coil

The technological characteristics of 0.32 painted aluminum coil :

- When the quality is qualified, the coated layer not have obvious indentation, omission or damage, and should not have ripples, scratches or blisters.

- Polyester paint is warranty to10 years, and fluorocarbon paint is warranty to more than 20 years.

- Flatness-No composite high temperature indentation on the surface. No residual stress on the sheet surface, no deformation after shearing。

- Weather resistance: The pattern made by patch coating and high temperature baking, high gloss retention, good color stability and little change in color difference。

- Decorative-wood grain, stone grain, realistic texture, natural and fresh. The pattern is as free as you like, providing customers with a wide range of personal choices, to enriched the humanistic connotation of the product, and giving people more aesthetic enjoyment.

- 0.32 painted aluminum coil The plate is a kind of aluminum coil, which is very good decorative. When buying, the customers not only pay attention to its performance, but also carefully check its appearance.

- The aluminum plate for curtain wall will also be processed by electrostatic spraying. Powder coated materials are mainly pigment raw materials with high color retention, such as polyurethane, intumescent resin, and epoxy resin. different colors powder can be obtained, and the decorative effect is very good.

0.32 painted aluminum coil Pencil Hardness (Dry Film Hardness) Test Standard:

Use a set of Zhonghua brand high-grade hardness test pencils with a minimum hardness of 1HB, with the end of the 3.5~6 mm pencil exposed.

Use sandpaper to smooth the pen core 90°. Make it 45° with the grinding layer, and push forward 6 mma forcefully (keep the pen core no broken), according to GB/T 6739.

Paint characteristics

- Good hardness and scratch resistance

- Lack of flexibility

| Item | Test Item | Standard | National standard | Test Result |

| 1 | Color Difference | ECCA T3 | ΔE≤2.0 | ΔE≤1.5 |

| 2 | Gloss Difference | ECCA T2 | ≤10 | ≤5 |

| 3 | Coating Thickness | ECCA T1 | Two layers Min 23μm | ≥25μm |

| Three layers Min 30μm | ≥34μm | |||

| 4 | Pencil Hardness | ASTM D3363 | ≥HB | HB |

| 5 | T-bend | ASTM D4145 | ≤2T | ≤2T |

| 6 | Adhesion | ASTM D3359 | Grade 0 | Grade 0 |

| 7 | Impact | ASTM D2794 | ≥50kg.cm | ≥50kg.cm |

| 8 | Boiling water Resistance | GB/T17748 | 2h No change | 4h No change |

| 9 | Solvent Resistance | ASTM D2248 | 200 times paints remaining | 500 times no break |

| 10 | Acidity Resistance | ASTM D1308 | 5%HCL 24hrs No change | No change |

| 11 | Alkali Resistance | ASTM D1308 | 5%NaOH 24hrs No change color △E≤2.0 | No change |

| 12 | Nitric acid Resistance | AAMA620 | △E≤5.0 | △E≤5.0 |

| 13 | Oil Resistance | ASTM D1308 | 20#oil 24hrs No change | No change |

| 14 | Salt Spray Resistance | ASTM B117 | 4000hrs ≤Grade 1 | No change |

| 15 | Abrasion resistance | ASTM D968 | ≥5L/μm | ≥5L/μm |

| 16 | Dirt Resistance | GB/T9780 | ≤5% | <5% |

| 17 | Color retaining | GB/T16259 | 4000 hrs△E≤4.0 | 4000 hrs △E≤3.0 |

| 18 | Gloss weaken Level | 4000 hrs ≤ Grade 2 | 4000 hrs ≤ Grade 2 | |

| 19 | Chalking | 4000 hrs No change | 4000 hrs No change |

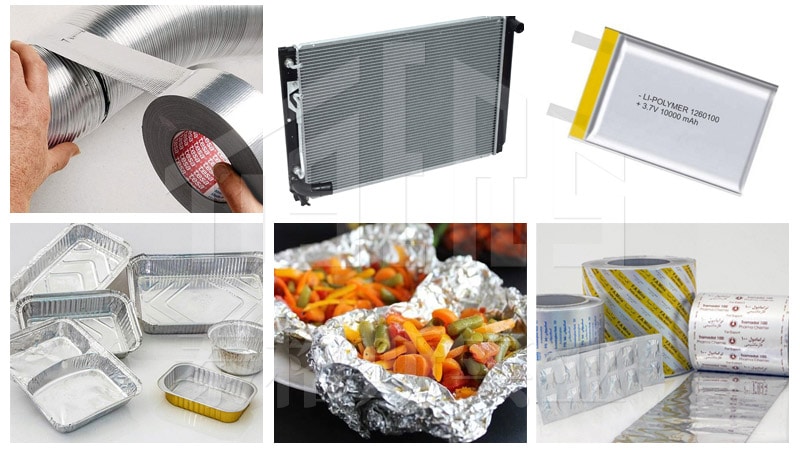

0.32 painted aluminum coilis a new type of decorative material, which have a wide usage and can be recycled. The fluorocarbon coating has many advantages such as antistatic, high durability, self-cleaning, fingerprint resistant, high strength, antistatic, thermal insulation and corrosion protection. It is the first choice material for replacing galvanized color coated coil. The product quality exceeds national standards and the factory wholesale price; and we also produce 3d wood grain effect, imitation wood grain, wooden, Gray, iron gray, white gray, silver gray, dark gray, blue sky pattern, orange peel and other color-coated aluminum sheet and coil, please contact us to get the accurate price of 0.32 painted aluminum coil!

Aluminum products of Tigers meet the export popular.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

There are 2 tons in one package, and loading 18-22 lots in 1×20′ container, and 20-24 tons in 1×40′ container.