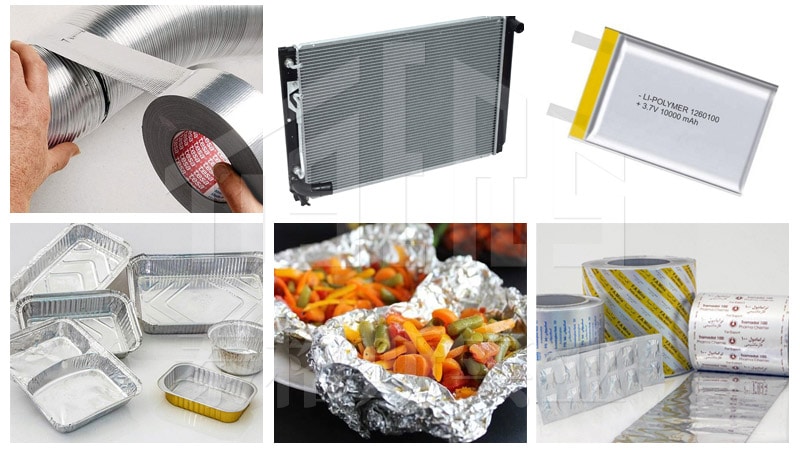

Can end is used to seal the top of the can, usually made of aluminum, and are an important barrier to maintaining the quality and safety of the product inside the can.

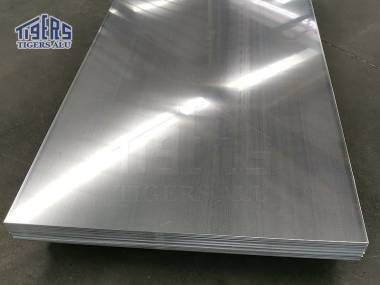

5042 h48 aluminum coil

Aluminum cans have become one of the most popular packaging materials for the beverage and food industry due to their light weight, durability and environmental friendliness.

What is 5042 H48 aluminum coil?

5042 H48 belongs to the 5000 series of aluminum alloys. It is an alloy of aluminum and magnesium with small amounts of other elements such as iron, zinc and silicon.H48 tempering means that the material is hardened and has some strength and good plasticity.

5042 (AW-AlMg3,5Mn) Chemical composition

| Mg | Fe | Zn | Si | Mn | Cu | Cr | Ti | Others | Al | |

| Each | Total | |||||||||

| 3.0-4.0 | 0.35 | 0.25 | 0.20 | 0.2-0.5 | 0.15 | 0.10 | 0.1 | 0.05 | 0.15 | Reste |

Features of 5042 H48 aluminum coil

High plasticity

5042 H48 aluminum coil has excellent plasticity, which is essential for the production of can ends with complex shapes and designs. This material can be deep drawn, stretched and bent without cracking or tearing.

Good corrosion resistance

The high magnesium content in 5042 H48 aluminum coil provides excellent corrosion resistance, making it suitable for use in environments with high humidity or exposure to slightly corrosive solutions.

Moderate strength

5042 aluminum coil’s H48 temper makes it moderately strong enough to withstand the stresses of carbonated beverages and other packaging products.

5042 H48 aluminum coil applications

5042 H48 aluminum coil is mainly used for can end production. The lid is the top cover that seals the can body and protects the internal wuben from contamination and oxidation.

blue aluminum can with end

Due to the good malleability and high strength of 5042 H48 aluminum coil, it can be easily made into various can ends and sizes, such as pull ring ends and stay ring lids. However, this material is not suitable for producing can bodies, which require a higher degree of ductility to keep them from tearing during the production process.

What are the alloys that can be used as raw materials for aluminum can ends?

Usually the following four alloys are used as raw materials for aluminum can ends by aluminum can lid purchasers.

3104 H48 aluminum coil

5182 H48 aluminum coil

5052 H48 aluminum coil

5042 H48 aluminum coil

And the raw material for manufacturing aluminum can body is 3104 H19 aluminum alloy.

Aluminum can body and can end video

Conclusion

In summary, 5042 H48 aluminum coil is the ideal material for the production of can lids thanks to its ease of forming, corrosion resistance and high strength.

5042 H48 aluminum coil supplier

Tigers Aluminum has many years of experience in producing 5042 H48 alloy aluminum coils. We strictly control the quality of our products during production. The products meet international standards and have obtained a number of certificates.

The 5042 alloy aluminum coils we supply are exported to many countries at reasonable prices, and we are a trustworthy supplier of 5042 H48 aluminum coils.

Its excellent performance ensures the safety and quality of the packaged product, making it a popular choice for the beverage and food packaging industry. However, due to its lack of ductility, it is not recommended for the production of can bodies that require deep punching.

Aluminum products of Tigers meet the export popular.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

There are 2 tons in one package, and loading 18-22 lots in 1×20′ container, and 20-24 tons in 1×40′ container.