What is 6061 aluminum sheet/plate?

6061 Aluminum Plate is an aluminum-silicon-magnesium alloy, strengthened by precipitation hardening.

6061 Aluminum Sheet & Plate offers a combination of higher strength, This sheet has good workability and good machinability, It is the highest in its class of heat treated aluminum when it comes to corrosion resistance.

KEY WORD: al6061, UNS A96061; ISO AlMg1SiCu; Aluminium 6061-T6, AD-33 (Russia); AA6061-T6; 6061T6, UNS A96061; ISO AlMg1SiCu; Aluminium 6061-T651, AD-33 (Russia); AA6061-T651.

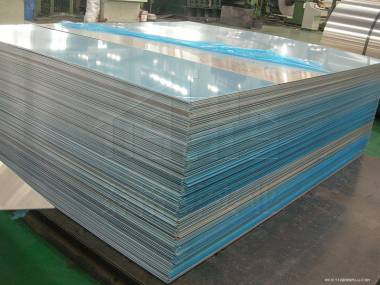

6061 t6 aluminum plate

This allows it to be used in heavy duty structures and marine environments. The 6061 grade is the most widely used aluminum sheet and plate grade available for all types of fabrication projects.

Aluminum 6061 sheet/plate composition (For Reference)

Chemical Composition conforms to Chinese, American, and European standard specification

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: Each other |

Others: Total |

Al: Min. |

| 6061 | 0.40~0.8 | 0.70 | 0.15~0.4 | 0.15 | 0.8~1.2 | 0.04~0.35 | 0.25 | 0.15 | 0.05 | 0.15 | remainder |

6061 aluminum sheet tensile strength range 20 to 42 KSI. Conforms to AMS QQ-A- 250/11 and ASTM B209.

The general purpose 6061 Aluminum Sheet & Plate is heat treatable, resists cracking due to stress, and is easy to weld and machine, but limited on formability.

8mm 6061 t4 aluminum plate

6061 aluminum properties

The welding capability of this product is great, allowing any method of welding to be used. Annealing can be performed, which will put it in a state to be easily cold worked. Any methods of cold working can be used for stamping, drilling, bending, deep drawing, tapping, and cutting.

When annealing this metal, it’s recommended that it be placed in 775 degrees F for between two and three hours, followed by a steady drop in the temperature by 50 degrees each hour, until it is down to 500 degrees F. Air cooling should be allowed afterward.

Other methods of heat treatment that can be used include solution heat treating, aging precipitation heat treating, and hot working.

| Imperial | Metric | |

| Density | 0.0975 lb/in3 | 2.7 g/cc |

| Ultimate Tensile Strength | 45,000psi | 310 MPa |

| Yield Tensile Strength | 40,000psi | 276 MPa |

| Fatigue Strength | 14,000psi | 96.5 MPa |

| Shear Strength | 30,000psi | 207 MPa |

| Melting Point | 1,080 – 1,205°F | 582 – 652°C |

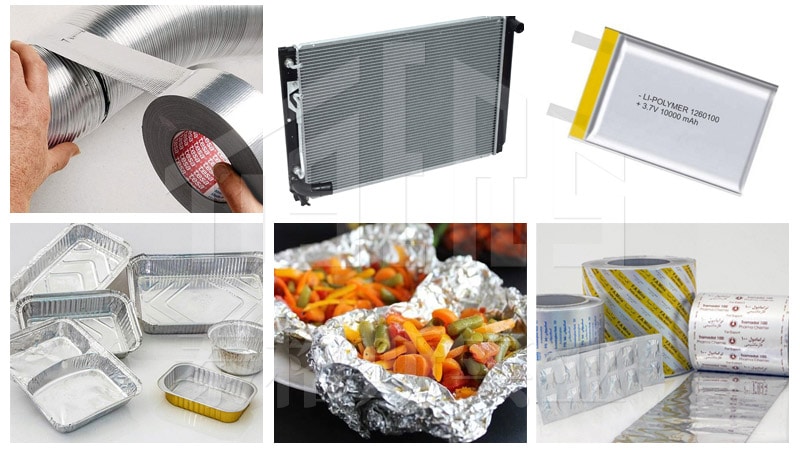

Aluminum 6061 sheet applications include a wide variety of products from medical assemblies, aircraft construction to structural components. 6061 t6 aluminum sheet has a high strength to weight ratio making it ideal for any application where parts need to be light.

| Alloy | Temper | Thickness (mm) |

Width (mm) |

Length (mm) |

| 6061 Aluminum Sheet / Plate | O, T4,T6,T651 | 0.3-500 | 500-2600 | 500-16000 |

Alloy 6061 coils and sheets are the most versatile of the heat treatable aluminum alloys. Though less strong than most of the 2xxx and 7xxx alloys, 6061 aluminum provides an extensive range of mechanical properties and corrosion resistance and can be fabricated by many of the commonly used practices.

In the “O” temper or annealed condition, alloy 6061 has good formability. In the T4 condition, fairly severe forming can be done; whereas, in the T6 condition, properties may be obtained by artificial aging.

Welding

6061 is highly weldable, for example using tungsten inert gas welding (TIG) or metal inert gas welding (MIG). Typically, after welding, the properties near the weld are those of 6061-T4, a loss of strength of around 40%. The material can be re-heat-treated to restore near -T6 temper for the whole piece. After welding, the material can naturally age and restore some of its strength as well.

Most strength is recovered in the first few days to a few weeks. Nevertheless, the Aluminum Design Manual (Aluminum Association) recommends the design strength of the material adjacent to the weld to be taken as 165 MPa/24000 PSI without proper heat treatment after the welding. Typical filler material is 4043 or 5356.

Extrusions

6061 is an alloy used in the production of extrusions—long constant–cross-section structural shapes produced by pushing metal through a shaped die.

Forgings

6061 is an alloy that is suitable for hot forging. The billet is heated through an induction furnace and forged using a closed die process. This particular alloy is suitable for open die forgings. Automotive parts, ATV parts, and industrial parts are just some of the uses as a forging.

Aluminum 6061 can be forged into flat or round bars, rings, blocks, discs and blanks, hollows, and spindles. 6061 can be forged into special and custom shapes.

Castings

6061 is not an alloy that is traditionally cast due to its low silicon content affecting the fluidity in casting. It can be suitably cast using a specialized centrifugal casting method. Centrifugally cast 6061 is ideal for larger rings and sleeve applications that exceed limitations of most wrought offerings.

Aluminum 6061 density

The density of 6061 aluminum alloy is 2.7 g/cm3 (0.0975 lb/in3), or about the same as pure aluminum metal.

5mm 6061 T6 aluminum plate

Alloy 6061 sheet metal specifications and applications

6061 Aluminum Sheet & Plate are ideal for structural framing, ggussetsaircraft, marine, automotive parts, tooling plate, architectural applications, transportation equipment, mountain bike, bridge railing components, etc, It is useful in welded structural applications.

It is precise because of the high strength, light weight, and low density of 6061 aluminum that the lightweight frames of bicycles from brands such as Schwinn bicycles, and Shimano bikes also use 6061 aluminum alloy.

6061 billet aluminum can also be made into aluminum pipe, aluminum bar, aluminum angle, and other shapes for industrial use.

Tigers aluminum stock 6061 Aluminum Plate in thickness 0.250” through 16” thick, between 48 and 96 inches wide, and up to 240 inches long in stock available for immediate delivery.

6061 aluminum sheet/plate stock is available in full size and custom cut lengths.

boat made of the aluminum sheet

One of the major benefits of opting for 6061 aluminum tooling plate is the versatility of the alloy. Ideal for everything from electronics and agriculture, it can also be used in storage tanks, hydraulic cylinders, pipework, construction,n and even for sporting goods.

A cost-effective option, 6061 T6 aluminum sheet, and related products are popular choices for customers that want a generic option that demonstrates excellent welding potential as well as the ability to be shaped as required.

An added advantage of using 6061 aluminum plate is that it is resistant to corrosion – a major benefit if your products are routinely exposed to the weather, moisture, or extreme temperature changes.

Aluminum Alloy 6061-T6 is perhaps the most common grade of Aluminum because of its good machinability and weldability.

| Thickness | 0.6mm, 0.7mm, 0.8mm, 1.2mm, 1.5mm, 1.6mm, 2mm, 3mm, 4mm, 5mm, 6mm |

| Size | 1220x2440mm, 1.22m x 2.44m, 1/8 inch |

6061 Aluminum Plate and Sheet Characteristics

- Heat-treatable

- Weldable

- Machinable

- Resists cracking

- Good corrosion resistance

- 6061 Aluminum Sheet Tempers

Alloy 6061 coils and sheets are the most versatile of the heat treatable aluminum alloys. Though less strong than most of the 2xxx and 7xxx alloys, 6061 aluminum provides an extensive range of mechanical properties and corrosion resistance and can be fabricated by many of the commonly used practices.

In the “O” temper or annealed condition, alloy 6061 has good formability. In the T4 condition, fairly severe forming can be done; whereas, in the T6 condition, properties may be obtained by artificial aging.

What is 6061-T4 Aluminium Plate?

Aluminium 6061 T4 Sheet is solution heat-treated and naturally aged giving it slightly lower tolerance accuracy than Aluminum 6061 T6, which undergoes artificial aging.

T4 is also slightly less expensive than T6 with a higher elongation percentage, which increases the formability of the T4 temper.

Aluminum sheet 6061 T4 is also cost friendlier and has improved formability over T6.

6061 T4 Aluminum Sheet Applications

Aluminum sheet 6061 T4 is used in many types of industrial applications, including:

- Aircraft panels

- Automotive panels

- Trailer frames

- Packaging

- Bike

- And more

What is 6061 T6 aluminum Sheet?

6061-T6 aluminum is 6061 aluminum in the T6 temper. 6061 T6 is one of the most common materials in the world. The T6 refers to the temper or degree of hardness, which is achieved by precipitation hardening. This grade has a good strength-to-weight ratio and is also heat-treatable.

To achieve this temper, the metal is solution heat-treated and artificially aged until it meets standard mechanical property requirements.

With great formability and weldability, it is used for engineering and structural applications, boats, furniture, and more.

6061 t6 aluminum is a high strength aluminum alloy. It is one of the most commonly used aluminum alloys in the world. It has good corrosion resistance and forms a hard oxide layer when exposed to air.

More details: aluminum 6061 t6 properties

The advantages of 6061-T6 Aluminum Plate

- Aluminum 6061-T6 is artificially aged.

- 6061-T6 has a higher tensile and yield strength than 6061-T4.

- Offers good finishing characteristics.

- Can be welded or joined.

- Can also be anodized.

6061-T6 Aluminum Sheet Applications

Common applications for 6061-T6 aluminum sheet include:

- bicycle frames and components.

- many fly fishing reels.

- the Pioneer plaque

- the secondary chambers and baffle systems in firearm sound suppressors (primarily pistol suppressors for reduced weight and improved mechanical functionality), while the primary expansion chambers usually require 17-4PH or 303 stainless steel or titanium.

- The upper and lower receivers of many non mil-spec AR-15 rifle variants.

- Many aluminum docks and gangways, welded into place.

- Material used in some ultra-high vacuum (UHV) chambers

- Many parts for remote controlled model aircraft, notably helicopter rotor components.

- Large amateur radio antennas.

- Fire department rescue ladders

6061 aluminium yield strength

6061-T6. T6 temper 6061 aluminium has an ultimate tensile strength of at least 42,000 psi (290 MPa) and yield strength of at least 35,000 psi (241 MPa). In thicknesses of 0.250 inches (6.35 mm) or less, it has elongation of 8% or more; in thicker sections, it has elongation of 10%.

When and why to use 6061-T651 Aluminium Plate?

For aluminum sheet thicknesses greater than .190″ please choose 6061-T651 Aluminium Plate.

Our 6061 plate has T651 temper, indicating it has been solution heat treated followed by a minimal stretching to reduce stresses in the material. The material was then artificially aged to allow the alloying elements to precipitate out of the material, to give immediate maximum strength.

6061-T651 Aluminum sheet is an excellent candidate for most processing techniques and both interior and exterior applications. Considered the most versatile of the heat treatable aluminum alloys, it offers good corrosion resistance.

It’s a lightweight material with a semi-smooth surface and a dull mill finish commonly machined to end user specifications in a variety of applications such as aircraft and trailers.

6061-T651 Aluminum Sheet/Plate detail

Aluminum 6061-T651 Sheet/Plate has best in class strength-to-weight ratio and an excellent corrosion resistance rating. 6061-T651 Aluminum Sheet/Plate has a wide range of applications due to its high machinability and weldability.

The aluminum alloy 6061-T651 should be used when strong but light components are a must and corrosion is a concern, some application examples include aerospace construction, bridge components, and structural components.

6061-T651 Aluminum Plate Applications

Applications for 6061-T651 aluminum plate include:

- Aircraft and aerospace components

- Heavy-duty machinery

- Ramps

- Stairs

- Base plates

- Heavy structures

Aluminum alloy with similar properties and uses to 6061 aluminum are 7075 aluminum,2024 aluminum,5052 aluminum,6063 aluminum。

6061 aluminum vs 7075?

Though there are many different types of aluminum, the two most popular are 6061 aluminum and 7075 aluminum.

What is the different between 6061 aluminum and 7075 aluminum?

This comparison will be done by looking at the following features of the two metals. Weight, strength, conductivity, durability, and machining.

Strength makes the primary difference between 6061 and 7075 aluminum. For example, 7075 exhibits very high strength-to-weight ratio. In fact, 7075 provides the greatest strength available in aluminum bar.

It is widely used in aircraft applications where light weight plus strength are required, not to mention a high exposure to heat.

6061 Aluminum is more commonly used in aircraft construction due to its low weight and high strength. The conductivity of this type of aluminum is lower than that of the other variety which leads to a less efficient power transfer if it is used in electric currents.

7075 Aluminum has higher strength and lower weight than 6061 aluminum but has lower hardness. This means it doesn’t hold up as well over time as 6061 aluminum does but can better withstand high temperatures.

While 6061 is used in products that need to be lighter weight, if you’re using it for a product that needs to be stronger, then you would want to go with 7075.

What is the difference between 6061 aluminum and 6063?

6063 is another commonly used grade of aluminum and is often compared to 6061. Both 6061 and 6063 are made up of magnesium and silicon as their primary alloying elements, meaning they exhibit many of the same properties.

The difference between 6061 and 6063 is mainly in the end use. 6063 is a common grade used for custom extrusions. Its high corrosion resistance and good formability make it one of most joinable alloys. 6061 features higher strength (tensile strength range is 20 to 42 KSI) than 6063.

More information on 6061 aluminum sheet/plate

5083 aluminum alloy VS. 6061 aluminum metal

What is the difference between aluminum sheet and aluminum plate?

Wikipedia of 6061 aluminum alloy

Aluminum products of Tigers meet the export popular.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

There are 2 tons in one package, and loading 18-22 lots in 1×20′ container, and 20-24 tons in 1×40′ container.