What is Pe Coated Aluminium Sheet?

PE coated aluminium sheet is a new kind of material, the surface is coated with a layer of polyethylene paint, so that the aluminum plate has uv protection, acid and alkali resistance, high weather resistance and other excellent properties, the life of outdoor used can be as long as 20 years.

Manufacture

We manufacture, supply and wholesale Pe(polyethylene) coated aluminium sheet in customized colors and patterns. Our products are widely used in China.

Tigers aluminum can produce according to the specifications customized by the customer. The professional color coating production line ensures the stable quality of the color aluminum plate, which is better than Baosteel PCM aluminum alloy plated color plate, and the manufacturer’s wholesale price is favorable.

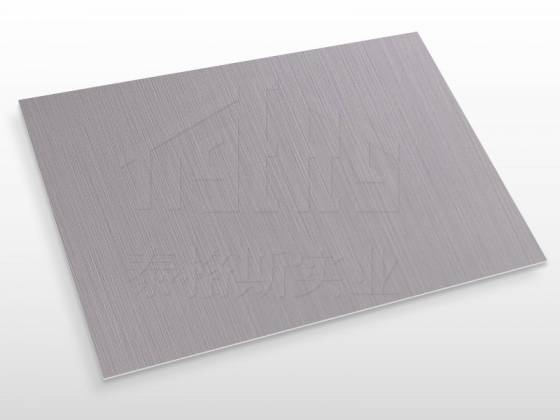

color coated aluminum sheet with gray brushed

PE coated aluminium sheet installation precautions:

The laying should pay attention to the perennial wind direction, the joint of the plate rib and the perennial wind direction.

The connection between them only overlaps one rib, and the female rib must be fastened above the male rib.

- gutter and the lower end of the bend about 10 degrees, forming a drip line.

- fixing screws should be perpendicular to the aluminum plate bottom and purlin and aligned with the center of the purlin.The stitching should be hung up before stitching to make the stitching line straight.

- for every 5-6 colored aluminum plate installed, the flatness of both ends of the plate shall be checked.If there are any mistakes, adjust them.If the aluminum plate is slightly tilted, adjust its alignment.Locking the fixed seat.

PE coated aluminium sheet specifications

| Thickness | 1.0mm, 1.5mm(indoor), 2.0mm, 2.5mm, 3.0mm (outdoor), 4.0mm, 5.0mm | ||

| Specification | 600*600mm 600*1200mm (Max width:1800mm Max length:8000mm) |

||

| Surface treatment | PVDF/ PE coating , Powder Spraying | ||

| Aluminum Alloy | 1100/3003/3105/3004/5052 | ||

| Application |

|

||

| Packing | Standard seaworthy export packaging. Wooden pallets with plastics protection for the coil and sheet. | ||

| Warranty | 10~15 Years based on different coating. | ||

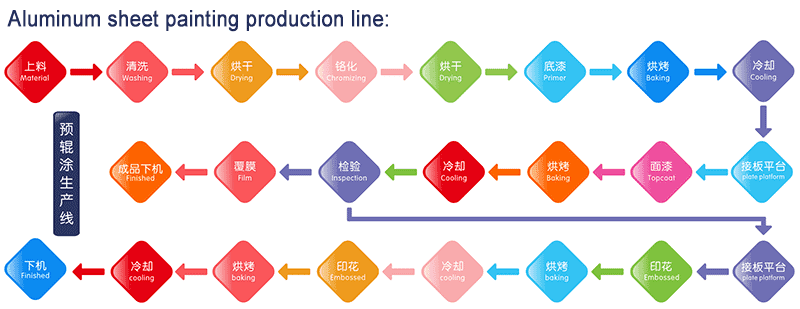

Aluminum sheet pre-roll coating process

Tigers paints solid color, wooden grain, brushed, marble grain, chameleon etc thick sheet painting production line.

Multi-layer painting process

Multilayer spraying process with three spraying(referred to as three sprays), spray bottom paint, topcoat and hood varnish and two spraying (primer, topcoat).

Coating thickness: It can be divided into single coating (4μm-20 μm); double coating (25μm-28 μm); 3 coating (35μm-38μm).

Advantages of PE coated aluminium sheet

- Smoothness:

- No compound high temperature indentation on the surface. There is no residual stress on the board surface and no deformation after shearing.

- Decorative:

- Painted with wood grain and stone grain, it has a realistic sense of solid material and a vivid natural beauty. The pattern is made at random, giving customers a wide range of individual choices, enriching the humanistic connotation of the product, and giving people more beautiful enjoyment.

- Weather resistance:

- The paint pattern formed by continuous coating and high-temperature baking has high gloss retention, good color stability, and minimal color difference. Polyester paint is guaranteed for 10 years, and fluorocarbon paint is guaranteed for more than 20 years.

- Mechanical:

- Select high-quality aluminum, plastics and adhesives, and use advanced composite technology. The product has the required flexural and flexural strength for decorative panels. In the four-season climate, changes in wind pressure, temperature, humidity and other factors will not cause bending, deformation, expansion, etc.

- Environmental protection:

- Resistant to salt-alkali and acid rain, it will not corrode itself to produce toxins, will not release any toxic gas, will not cause corrosion of the keel and fixed parts, and is flame retardant. According to national regulations, no lower than B1 level.

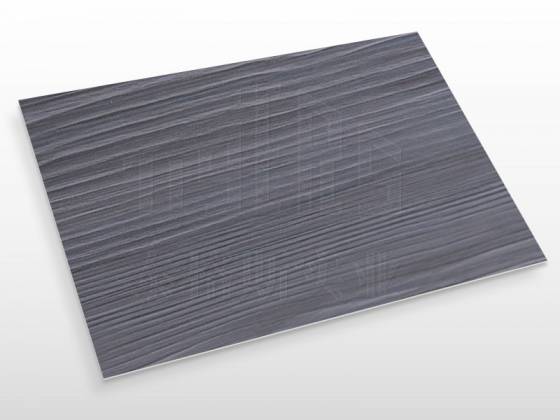

color coated aluminum sheet with black

The performance of PE color coated coil/sheet

| Item | Test Item | Standard | National standard | Test Result |

| 1 | Color Difference | ECCA T3 | ΔE≤2.0 | ΔE≤1.5 |

| 2 | Gloss Difference | ECCA T2 | ≤10 | ≤5 |

| 3 | Coating Thickness | ECCA T1 | Min 14μm | ≥16μm |

| 4 | Pencil Hardness | ASTM D3363 | ≥HB | HB |

| 5 | T-bend | ASTM D4145 | ≤3T | ≤2T |

| 6 | Adhesion | ASTM D3359 | Grade 0 | Grade 0 |

| 7 | Impact | ASTM D2794 | ≥20kg.cm | ≥20kg.cm |

| 8 | Boiling water Resistance | GB/T17748 | 2h no change | 2h no change |

| 9 | Solvent Resistance | ASTM D2248 | 200 times paint remaining | 200 times paint remaining |

| 10 | Salt Resistance | ASTM B117 | 720 hrs≤grade 1 | 720hrs≤grade 1 |

| 11 | Dirt Resistance | GB/T9780 | ≤5% | <5% |

| 12 | Color retaining | GB/T16259 | 600hrs △E≤2.0 | △E≤2.0 |

| 13 | Gloss weaken Level | 600hrs ≤ grade 2 | 600hrs ≤ grade 2 | |

| 14 | Chalking | 600hrs No Change | No Change |

| Item | Test Item | Standard | National standard | Test Result |

| 1 | Color Difference | ECCA T3 | ΔE≤2.0 | ΔE≤1.5 |

| 2 | Gloss Difference | ECCA T2 | ≤10 | ≤5 |

| 3 | Coating Thickness | ECCA T1 | Min 14μm | ≥18μm |

| 4 | Pencil Hardness | ASTM D3363 | ≥HB | HB |

| 5 | T-bend | ASTM D4145 | ≤3T | ≤2T |

| 6 | Adhesion | ASTM D3359 | Grade 0 | Grade 0 |

| 7 | Impact | ASTM D2794 | ≥50kg.cm | ≥50kg.cm |

| 8 | Boil Resistance | GB/T17748 | 2hrs No change | 2hrs No change |

| 9 | Solvent Resistance | ASTM D2248 | 200 times paint remaining | 200 times paint remaining |

| 10 | Salt Resistance | ASTM B117 | 720hrs ≤ grade 1 | 720hrs ≤ grade 1 |

| 11 | Acidity Resistance | GB/T9780 | ≤5% | <5% |

| 12 | Color retention | GB/T16259 | 600hrs △E≤2.0 | △E≤2.0 |

| 13 | Gloss weaken Level | 600hrs ≤grade 2 | 600hrs ≤ grade 2 | |

| 14 | Chalking | No change | No change |

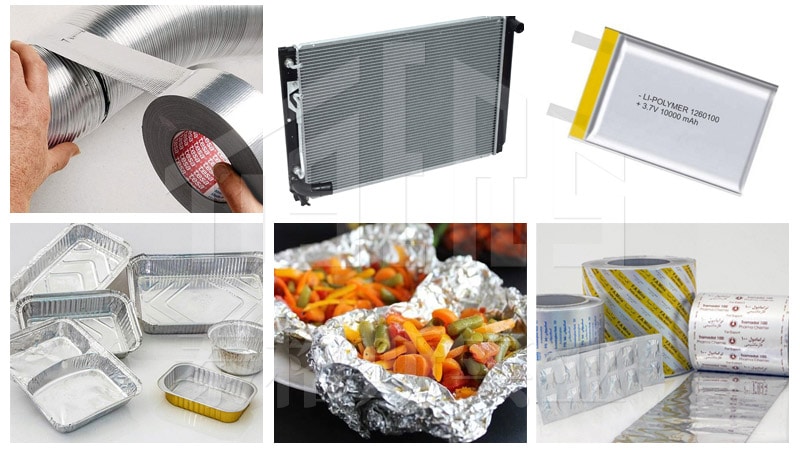

Application of PE powder coated aluminium sheet

PE(polyethylene) coated aluminium sheet are widely used in architectural decoration, food packaging, electronic appliances, printing, transportation and other fields.

Fluorocarbon coating aluminium sheet (PVDF) : Fluorocarbon coating is a PVDF resin, mainly refers to the copolymer of vinylidene fluoride homopolymer or Vinylidene fluoride with a small amount of other vinylidene fluoride monomers.

The stability and fastness of the chemical structure make the physical properties of fluorocarbon coatings different from those of ordinary coatings.

In addition to the mechanical properties of wear resistance, impact resistance also has excellent performance, especially in bad weather and environment show long-term anti-fading, anti-ULTRAVIOLET ability.

Fluorocarbon coatings can be divided into traditional fluorocarbon coatings and nano-fluorocarbon coatings according to their surface film-forming structure.

PE coated aluminium sheet Type Inspection

Type inspection should be carried out when one of the following situations is encountered:

- a) Experimental finalization and appraisal of new products or old products transferred to factories;

- b) After formal production, if there are major changes in structure, material, process, which may affect product performance;

- c) When the product has been discontinued for more than half a year and production is resumed;

- d) Normal production is inspected once a year, and the resistance to neutral salt spray, artificial weathering and accelerated aging, and humidity and heat resistance are inspected every two years;

- e) When there is a big difference between the factory inspection result and the last type inspection.

coated aluminum sheet with dark gray wood grain

The coating of PE coated aluminium sheethas many excellent characteristics such as fingerprint resistant, anti-fading, antibacterial, thermal insulation and corrosion protection, high strength, high durability, antistatic etc .

We also produce orange peel, reticulated, 3d wood grain effect, imitation wood grain, wooden, imitation brick pattern, black and other color coated aluminum coil products.

PE coated aluminium sheet is a new decorative material, widely used, recyclable, is the preferred material to replace steel galvanized coated plate,high product quality better than the national standard, factory price;We also produce plain, blue sky pattern, sand effect, imitation copper, green grass pattern and other color coating aluminum coil products, welcome to contact us for accurate PE coated aluminium sheet prices and free sample.

Aluminum products of Tigers meet the export popular.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

There are 2 tons in one package, and loading 18-22 lots in 1×20′ container, and 20-24 tons in 1×40′ container.