Are you looking for packaging solutions for your pharmaceutical products? One of the most popular and effective packaging materials for medications is pharmaceutical foil., a versatile and reliable material that offers a range of benefits for both manufacturers and consumers.

Medical cold forming alu alu pharmaceutical foil

Pharmaceutical products require packaging that ensures their safety, stability, and efficacy while being easy to use and transport, It is especially important to choose suitable packaging materials.

What is Pharmaceutical Foil?

Pharmaceutical foil(Medicinal Aluminum Foil) is a thin, flexible, and impermeable sheet made of aluminum or aluminum alloys that are specifically designed for pharmaceutical packaging applications.

It is available in different thicknesses, widths, and lengths, and can be customized to meet specific packaging requirements.

Pharmaceutical foil is widely used for packaging solid, semi-solid, and liquid dosage forms, such as tablets, capsules, powders, creams, ointments, and liquids.

Ptp aluminum foil for blister packaging

The foil is typically coated with a layer of heat-sealable lacquer to ensure the stability and safety of the product inside. The thickness of the foil can vary depending on the specific requirements of the medication, but it is generally between 0.006-0.05mm.

There are two main types of pharmaceutical foil: blister foil and strip foil. Blister foil is used to package individual tablets or capsules, while strip foil is used to package multiple tablets or capsules in a single strip.

Benefits of Pharmaceutical Foil

Protection

Pharmaceutical foil provides excellent protection against moisture, light, oxygen, and other external factors that can compromise the quality and safety of medications.

Convenience

Pharmaceutical foil is easy to handle, store, and transport. It can be folded, cut, and sealed with ease, making it ideal for a variety of packaging configurations, such as blisters, sachets, pouches, and tubes. Additionally, it is lightweight and takes up less space than other packaging materials, reducing shipping and storage costs.

Customization

Pharmaceutical foil can be customized to meet specific packaging requirements, such as color, printing, embossing, and perforation.

Cost-effectiveness

Pharmaceutical foil is a cost-effective packaging solution that offers a high level of protection, convenience, and customization at a reasonable cost. It is also recyclable, making it an environmentally mfriendly option for pharmaceutical packaging.

Color aluminum foil gold

Properties of Pharmaceutical Foil

Pharmaceutical foil has several unique properties that make it an ideal choice for packaging pharmaceutical products. Some of these properties include:

- Impermeability: Pharmaceutical foil is impermeable to light, air, moisture, and other external factors that can compromise the quality and safety of the medication. This helps to extend the shelf life of the product and protect it from degradation.

- Barrier Properties: The foil provides an excellent barrier against gas, vapor, and UV rays. This is especially important for medications that are sensitive to light and heat.

- Formability: Pharmaceutical foil is highly formable, allowing it to be easily shaped, folded, and cut into a variety of packaging configurations.

- Compatibility: The foil is compatible with a wide range of drugs and can be used for both sterile and non-sterile products. It is also suitable for both cold-forming and thermoforming processes.

Applications of Pharmaceutical Foil

Pharmaceutical foil has many applications in the pharmaceutical industry, including:

- Blister Packaging: The foil is commonly used to package tablets, capsules, and other solid dosage forms in blister packs. This helps to protect the medication from external factors and provide a tamper-evident seal.

- Strip Packaging: The foil can also be used in strip packaging, which is a convenient and cost-effective way to package medications in a single dose.

- Sachets and Pouches: The foil is often used in sachets and pouches for liquids, creams, and gels. This provides a lightweight and portable packaging solution that is easy to use and dispose of.

Overall, pharmaceutical foil remains a popular and effective packaging solution for the pharmaceutical industry. With its ability to protect and preserve medications, it plays a crucial role in ensuring the safety and efficacy of drugs worldwide.

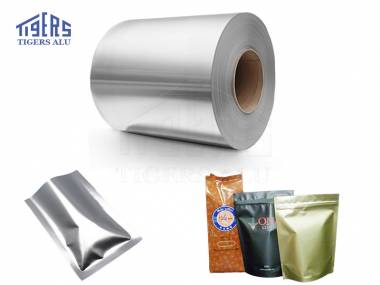

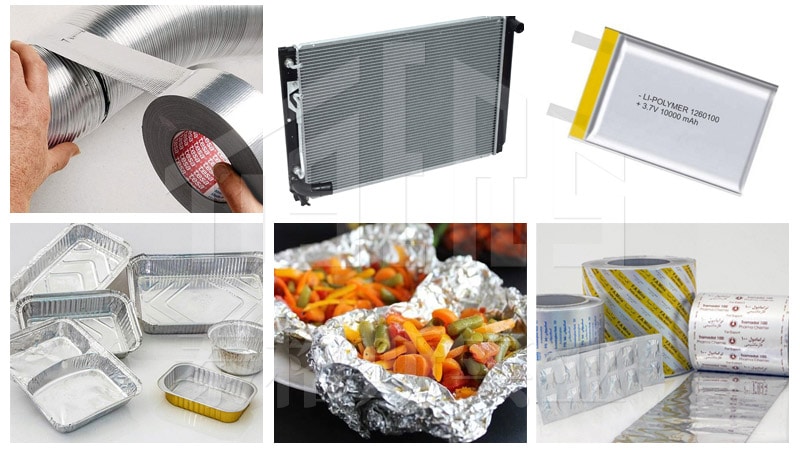

Different types of aluminum foil

There are many uses for aluminum foil, and the different types of foil commonly found are.

- Household aluminum foil

- Aluminum foil for containers

- Flexible packaging foil

- Pharmaceutical foil

- Electronic foil

- Air duct material

- Hydrophilic aluminum foil

- Beauty hairdressing aluminum foil

- Beer foil

- Adhesive tape foil

- Aluminum foil for capacitors

- Cable foil

Which aluminum alloys can be used to make pharmaceutical foils?

Pharmaceutical foil is a necessary material for medicine packaging. The alloys that can be used to make medicine foil are:

FAQs

What is pharmaceutical foil made of?

Pharmaceutical foil is made up of several layers of material, including a PVC or PET film, aluminum foil, and a heat-seal coating.

What is the difference between blister foil and strip foil?

Blister foil is used to package individual tablets or capsules, while strip foil is used to package multiple tablets or capsules in a single strip.

Is pharmaceutical foil recyclable?

While the foil is technically recyclable, it is not widely accepted by recycling programs due to its thinness and mixed composition with other materials.

Can pharmaceutical foil be used for sterile products?

Yes, pharmaceutical foil is suitable for both sterile and non-sterile products.

Aluminum products of Tigers meet the export popular.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

There are 2 tons in one package, and loading 18-22 lots in 1×20′ container, and 20-24 tons in 1×40′ container.