The Difference Between Hot-rolled Aluminum Sheet DC And Continuous Casting rolling Aluminum Plate CC?

What is Hot-rolled Aluminum Sheet(DC) and Casting rolling(CC)?

Hot-rolled aluminum sheet generally refers to the rolling of metal above the crystallization temperature.

Casting rolling aluminum sheet is also called cast aluminum sheet, cold rolling usually refers to the rolling of metal below the recrystallization temperature.

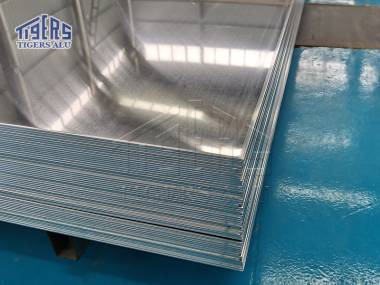

3mm aa1050 h14 aluminum sheet

Performance of DC and CC

Casting rolling (CC) and hot-rolled (DC) are different in performance, the cast-rolled aluminum discs have poor deep drawability compared to hot-rolled aluminum discs and are rarely used for deep drawing.

Compared with ordinary cast-rolled products, the hot-rolled aluminum sheet has good surface quality, while the mechanical properties, as well as ductility, are stronger and the oxidation effect is good.

packages of aluminum sheet

Cold-rolled aluminum sheet produces work hardening, an increase in the strength and deformation resistance of the metal, accompanied by a decrease in plasticity.

How to choose DC or CC aluminum?

In the choice of aluminum plate, must pay attention to the use of aluminum plate, if the mold with cold-rolled aluminum plate, then the mold made in terms of hardness and durability is not as good as the cold-rolled plate. And cold-rolled aluminum sheet is used for stamping and drawing processing, because of the weak tensile ability and high hardness of cold-rolled aluminum sheet, it is easy to fracture.

Different between CC and DC

- The cold rolled aluminum sheet with CC materials is simple in process and the price is cheaper than the hot rolled aluminum sheet with DC materials.

- The raw material supply is different: the difference between the two in the supply of billet material is not the same.

Hot-rolled material: aluminum ingots – melting and casting into flat ingots – milling – homogenization annealing – hot-rolled into sheets and strips.

Cold rolled material: ingots – melted – rolled into strips by casting and rolling mill.

Compared with the two, cold-rolled material production efficiency, but for example, like the composition of deviations, inclusions and other defects are not easy to solve, the quality is not as good as hot-rolled material; - The production process is different: cold-rolled is a casting mill processing into a cast roll (8mm thickness) through the cold rolling mill processing, and hot-rolled is an aluminum ingot (400-500mm thickness) heating, in the high temperature by the hot rolling mill rolling from;

- Different performance: hot-rolled aluminum surface quality, while the mechanical properties and ductility of stronger, good oxidation effect, usually cold-rolled products have a lower elongation than hot-rolled products.

- The use of different, cold-rolled aluminum sheet more for the mold class, hot-rolled aluminum sheet suitable for stamping and drawing aspects.

aluminum sheet with blue films

Tigers aluminum can produce 0.4-6.0mm thick sheets of 1000 series, 3000 series, and 5000 series, the alloys are mainly 1050 1060 1100 3003 3004 3005 and 5052, the temper is mainly O(soft) for further processing into kitchen utensils.