What is Aluminum Fin Stock?

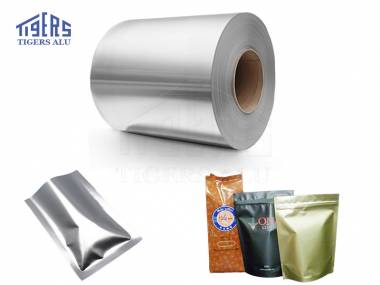

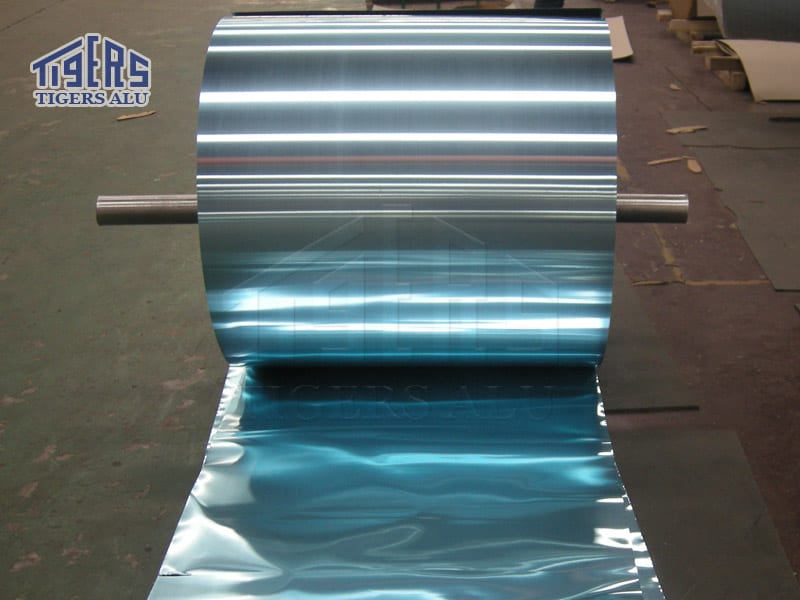

Aluminum fin stock is a lightweight, formable, and corrosion-resistant aluminum alloy material. It is typically produced by multiple passes of aluminum foil through aluminum foil rolling mills using 1000, 3000, and 8000 series aluminum alloy metals, resulting in thin and flat metal sheets. These sheets are usually in the form of aluminum coils but can also be cut into aluminum strips.

hydrophilic aluminum foil for Aluminum fin stock

The Importance of Aluminum Fin Stock

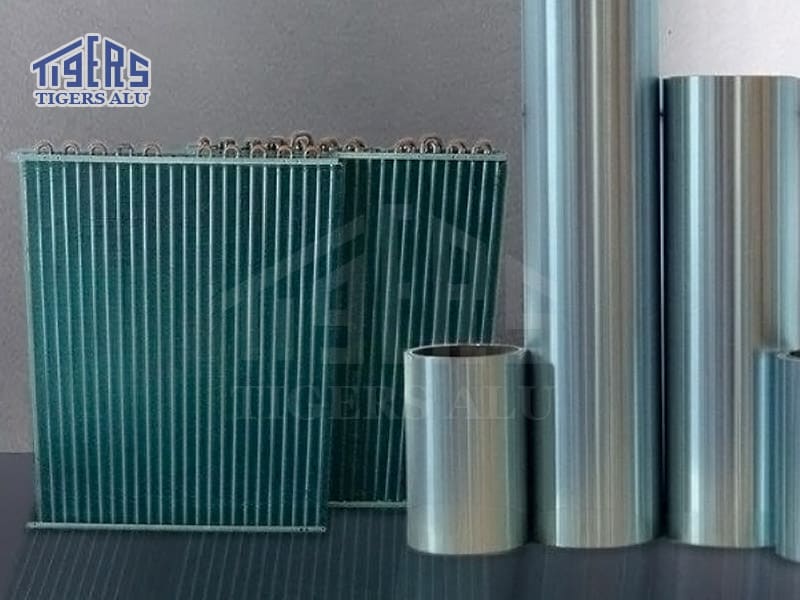

Aluminum fin stock plays a vital role in the HVAC (Heating, Ventilation, and Air Conditioning) industry. It serves as the primary material for manufacturing heat exchanger fins, which are crucial components of HVAC systems. The quality and performance of the fins directly impact the efficiency and durability of the entire system. Therefore, choosing a reliable supplier like Tigers Aluminum is important.

Hydrophilic aluminum foil roll

Specifications of Aluminium fin stock

| Alloy | Temper | Thickness(mm) | Width (mm) | I.D.(mm) | Mechanical Properties | ||

| Tensile Strength (Mpa) | Elongation(%) | Erichson (IE,mm | |||||

| 1100 1200 3102 8011 8006 |

O | 0.08-0.2 (+/-5%) |

100-1400 (+/-1) |

I.D.75/150/ 200/300/505 |

80-110 | ≥27 | ≥6.0 |

| H22 | 100-135 | ≥22 | ≥5.5 | ||||

| H24 | 115-145 | ≥20 | ≥5.0 | ||||

| H26 | 125-160 | ≥10 | ≥4.5 | ||||

| H18 | ≥160 | ≥1 | – | ||||

| Special specifications can be produced as per customer’s requirements | |||||||

Chemical Composition of Different Alloy Aluminum Fin Stock

| Alloy (%) | AA1050 | AA1100 | AA1200 | AA3003 | AA8006 | AA8011 |

| Fe | 0.40 | 0.95 | 1.00 | 0.70 | 1.40 — 1.60 | 0.6 — 1.00 |

| Si | 0.25 | (Fe + Si) | (Fe + Si) | 0.60 | 0.02 | 0.5 — 0.90 |

| Mg | 0.05 | – | – | – | 0.02 | 0.05 |

| Mn | 0.05 | 0.05 | 0.05 | 1.0 — 1.50 | 0.4 — 0.50 | 0.20 |

| Cu | 0.05 | 0.05 — 0.20 | 0.05 | 0.05 — 0.20 | 0.05 | 0.10 |

| Zn | 0.05 | 0.10 | 0.10 | 0.10 | 0.05 | 0.10 |

| Ti | 0.03 | – | 0.05 | 0.1(Ti+Zr) | 0.03 | 0.08 |

| Cr | – | – | – | – | – | 0.05 |

| Each(Others) | 0.03 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| Total (Others) | – | 0.15 | 0.125 | 0.15 | 0.15 | 0.15 |

| Al | 99.50 | 99.00 | 99.00 | Remainder | Remainder | Remainder |

Types of Aluminum fin stock

Aluminum fin stock raw materials are categorized into coated and uncoated types.

Coated Aluminum Fin Stock

Coated aluminum fin stock developed by Tigers Aluminum possesses excellent brazing capabilities, resistance to core dissolution and high-temperature collapse, making heat exchangers lighter.

Aluminum fin stock material

Uncoated Aluminum Fin Stock

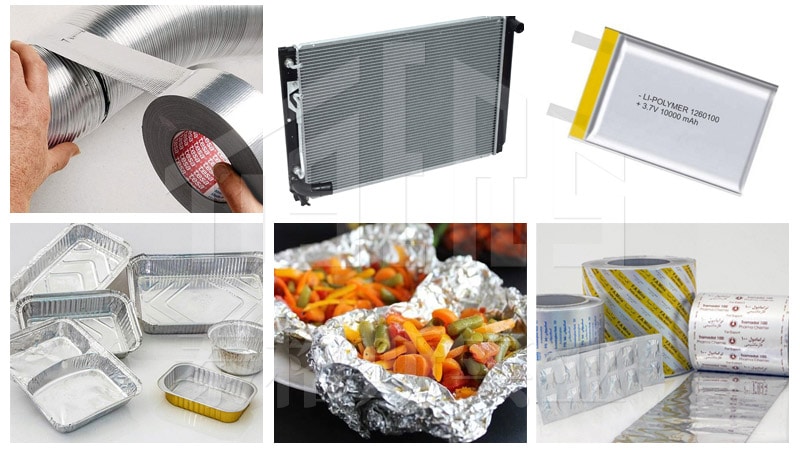

Uncoated aluminum fin stock is the most basic heat exchanger material. It consists only of a core layer without any coating. It can be used in various applications, including automotive radiators, intercoolers, oil coolers, evaporators, water tanks, heaters, and various air conditioning radiators.

Different Classifications of Uncoated Aluminum Fin Stock

1. Bare (Uncoated) Aluminum Fin Stock:

Bare aluminum fin stock is essentially a silver-colored sheet. It is an aluminum foil that has been rolled and annealed without any form of surface treatment. Currently, bare aluminum foil accounts for less than 50% of the aluminum foil used in air conditioning. Fifteen years ago, bare aluminum foil was the mainstream.

2. Pre-coated Aluminum Fin Stock:

The surface of pre-coated foil undergoes treatment and provides more functionalities compared to uncoated foil. Many countries have started using pre-coated aluminum foil in the past 10-15 years. Many corrosion-resistant aluminum foils and hydrophilic aluminum foils mentioned below can be classified as pre-coated aluminum foils.

3. Corrosion-Resistant Aluminum Fin Stock:

As the name suggests, corrosion-resistant aluminum fin stock is coated with a corrosion-resistant protective layer. Corrosion-resistant aluminum foil not only allows the use of air conditioners in harsh environments, improving their lifespan, but also contributes to better ventilation quality. Therefore, it is widely used.

4. Hydrophilic Aluminum Fin Stock:

Hydrophilic aluminum fin stock has a surface with strong hydrophilicity and a certain degree of corrosion resistance. Its main function is to exhibit hydrophobic properties, preventing water droplets from “bridging” between heat exchange fins and affecting the ventilation efficiency of the heat exchanger. This can improve the heat exchange rate of air conditioners and save electricity costs. In the past, conventional hydrophilic aluminum foils on the market not only had good hydrophilic properties on the surface but also had high corrosion resistance, optimizing the performance of air conditioners.

5. Superhydrophobic Aluminum Fin Stock:

Superhydrophobic aluminum fin stock, also known as superhydrophobic aluminum foil, has surface characteristics opposite to hydrophilic aluminum foil. Its purpose is to prevent condensation water from remaining between heat exchange fins. The difference is that superhydrophobic aluminum foil increases the contact angle between condensation water and heat exchange fins, allowing condensation water to form easily removable droplets, thereby eliminating condensation water between heat exchange fins.

6. Self-Lubricating Aluminum Fin Stock:

Self-lubricating aluminum fin stock does not require the addition of lubricating oil during the punching process. Lubrication during punching is provided by a thin film on the surface of the aluminum foil after pre-treatment. Since there is no need to add lubricating oil, subsequent cleaning and drying processes using trichloroethylene are also eliminated.

7. Anti-Mildew Aluminum Fin Stock:

Anti-mildew aluminum fin stock is mainly used in the indoor unit’s air conditioning dehumidification section. Its main function is to prevent the surface of heat exchange fins from becoming moldy due to long-term use or storage, thereby improving the ventilation quality of air conditioners.

Applications of Aluminum Fin Stock

Aluminum fin stock finds extensive use in the HVAC industry for the production of heat exchanger fins. Additionally, it is widely employed in the automotive industry for manufacturing radiators and condensers. Its excellent heat transfer properties, lightweight nature, and corrosion resistance make it an ideal choice for these applications. Tigers Aluminum provides aluminum fin stock that meets the stringent requirements of these industries, ensuring optimal performance and reliability.

car condenser radiator fin stock

Tigers Aluminum: A Strong and Technologically Advanced Company

At Tigers Aluminum, we boast state-of-the-art aluminum foil rolling mills and advanced production processes, ensuring our aluminum fin stock products meet the highest quality standards and consistency. We source high-quality aluminum alloy raw materials, including 1100, 1200, 3102, and 8011, to ensure exceptional performance and durability. Our aluminum fin stock exhibits outstanding thermal conductivity, corrosion resistance, and formability, making it an ideal choice for demanding applications.

air conditioning condenser fin stocks

Customization Options

We understand that every customer has unique requirements. That’s why Tigers Aluminum offers customizable options for aluminum fin stock. From dimensions to thicknesses, we can tailor the product specifications to meet your specific needs. Our flexible manufacturing processes allow us to produce aluminum fin stock in various sizes and thicknesses, ensuring a perfect fit for your applications.

Packaging

Tigers’ flat fins are packaged on wooden pallets in an “eye-to-sky” or “eye-to-wall” manner, wrapped with HDPE fabric and hard fiberboard, and strapped with iron bands. Silicone packaging ensures moisture resistance, and finally, the entire packaged product is placed in a wooden crate.

Tigers Aluminum is a aluminum fin stock supplier, and we have years of experience supplying composite and non-composite aluminum fin stock for heat exchangers, intercoolers, condensers, and evaporators at reasonable prices. Contact us now for additional discounts.

FAQ:

What is fin stock used in?

Aluminum fin stock finds extensive use in various applications, including heat exchangers for room/package air conditioners and large refrigerators. Its excellent thermal conductivity makes it an ideal choice for efficiently transferring heat in these systems.

Why is aluminum used in fins?

Aluminum is widely used in fins due to its exceptional properties such as excellent corrosion resistance, high formability, and superior thermal conductivity. These qualities make it the perfect material for constructing heat exchangers, ensuring optimal performance and durability.

What is the best material for fins?

The heat transfer performance of fins varies depending on the material used. Copper fins provide the highest heat transfer efficiency, while aluminum fins offer a good balance between performance and cost-effectiveness. On the other hand, steel fins have lower heat transfer capabilities compared to aluminum fins.

Compared to other materials, aluminum fins have better heat dissipation capabilities and lower costs. Therefore, aluminum is commonly used as the material for radiators.

Aluminum products of Tigers meet the export popular.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

There are 2 tons in one package, and loading 18-22 lots in 1×20′ container, and 20-24 tons in 1×40′ container.