The 2 main reasons for choosing Mill finish aluminum:

Aluminum is versatile and relatively low-cost. It has a high strength-to-weight ratio and possesses non-corrosive properties. It is environmentally friendly and can accept high-performance coatings.

Reason #1: Finishes can improve corrosion resistance.

Aluminum has a naturally occurring oxide film that protects it from corrosion. This oxide film is sufficient for many applications. But in extreme environments, extra protection may be needed.

Reason #2: Finishes can enhance the appearance of the aluminum.

Depending on the look you are trying to achieve, You need to choose the right finish. Maybe you want something that’s brightly colored. Maybe you’re trying to achieve a “mirror” finish. You need to choose a finish that will give you the look you want to achieve.

What is meant by “Mill Finish”?

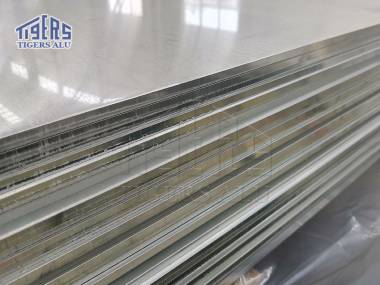

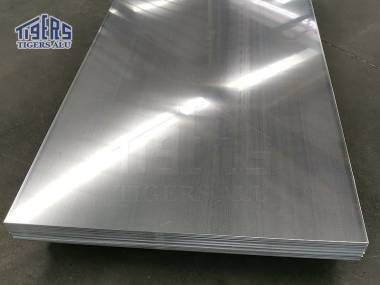

“Mill Finish” is the term that Tigers aluminum uses to describe its aluminum trims that have no finish applied to them. It is raw aluminum from our mill and it can be field primed and painted. Typically, Mill Finish has a shiny or “mirror-like” appearance with some visible manufacturing lines.

What is meant by “Mill Finish” is aluminum in its original form and appearance as its comes directly from the rolling mill or an aluminum extrusion mill.

Here are 6 different types of finishes for extruded aluminum:

- #1 Mechanical Finishes.

- #2 Pretreatment. The aluminum is either etched or cleaned with alkaline or acidic materials.

- #3 Bright Dipping.

- #4 Anodizing.

- #5 Liquid Paint.

- #6 Powder Coating.

- #7 Sublimation.

Here are some of the mill finish aluminium sheets produced by Tigers aluminium to help you have a better understanding.

5042 H48 can end aluminum coil

5042 H48 aluminum coil is 5042 aluminum alloy tempered to H48 state, it is often used to make aluminum can end.

5182 H48 aluminum coil for can end

5182 H48 aluminum coil is 5182 aluminum alloy tempered to H48 state aluminum can end material, it is used to make can beverage, beer and food packaging lid

5052 H48 aluminum coil for can end

Tigers Aluminum is a supplier of 5052 H48 aluminum coil for can end, which is strong, easy to form, and corrosion resistant.

3104 H48 aluminum coil for can end

3104 H48 aluminum coil is commonly used in the production of aluminum can end, such as beverage cans, beer cans and other products can lids.

3104 H19 aluminum coil for can body

3104 H19 aluminum is a type of aluminum product made from 3104 aluminum alloy tempered to the H19 state, which is often used as aluminum can body material for beverage cans, beer cans and cans.

6063 aluminum plate

High quality 6063 aluminum plate manufacture,Factory and Suppliers in China

5182 aluminum sheet

5182 aluminum alloy can be used as can lid material. Tigersalu is a manufacturer and stockist of 5182 aluminum sheet / coil in China with reasonable price and best quality.

3104 aluminum

3104 aluminum alloy main alloying addition is manganese, it has high tensile strength ≥ 275Mpa, elongation up to 20%, excellent deep drawing and ductility. The most common applications are beverage cans and beer cans.

5005 Aluminum Sheet

5005 aluminum sheet and plate contains 0.8% magnesium, It has medium strength, good weldability, commonly available in flat rolled aluminum coil, sheet and plate from a wide range of producing mills.

Here are 6 different types of finishes for extruded aluminum:

#1 Mechanical Finishes

Aluminum can be buffed, blasted, polished, grinded or sanded. These finishes can improve surface quality or prepare the aluminum for other cosmetic finishes.

#2 Pretreatment

The aluminum is either etched or cleaned with alkaline or acidic materials. Then a pretreatment coating is applied. This coating enhances powder or paint adhesion and provides resistance against corrosion.

#3 Bright Dipping

An extrusion can be bright dipped, giving the aluminum a specular or “mirror” finish. To do this, technicians put the profile into a special dip solution (a combination of hot phosphoric and nitric acids). After bright dipping, profiles can also be anodized, thickening the metal’s corrosion-resistant oxide layer.

#4 Anodizing

This electrochemical process provides additional protection aside from the natural oxide film. A durable, porous anodic oxide layer is formed on the surface of the aluminum. Anodized aluminum will also accept vibrant colors. You can anodize any kind of aluminum alloy.

#5 Liquid Paint

These coatings come in many colors and provide a uniform film thickness. Liquid coatings generally contain volatile organic compounds (VOCs). They are driven off during the curing or baking process. When the VOCs are gone the volume solids form a film on the extrusion.

#6 Powder Coating

Powder coatings leave behind a film that can meet stringent performance criteria. At the same time, they do not contain VOCs. This is ideal for meeting environmental regulations on VOCs. The product is applied as a solid on the extrusion. While going through the oven process, solid particles fuse together to form the film.

#7 Sublimation

Have you ever seen aluminum extrusions that look like wood? After applying a base coat of powder, profiles can go through sublimation. Technicians wrap the profiles in a thin film with a pattern on it. The sublimation process transfers that pattern directly onto the extrusions.

Packing

Aluminum products of Tigers meet the export popular.Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

There are 2 tons in one package, and loading 18-22 lots in 1×20′ container, and 20-24 tons in 1×40′ container.