What is aluminum 6061 t6 properties?

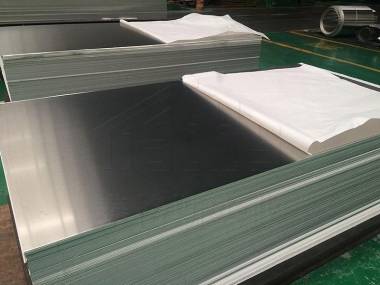

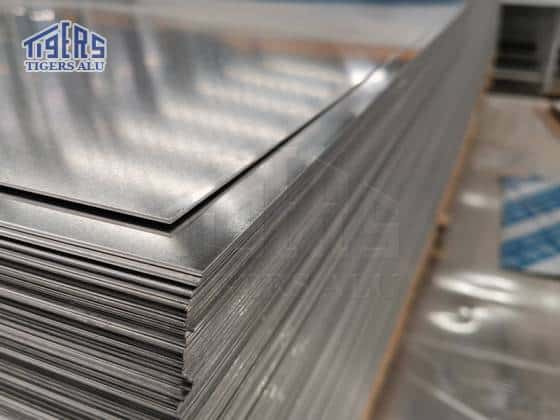

What is 6061 aluminum Sheet?

6061 t6 aluminum is an alloy that is very strong and durable. The corrosion resistance of 6061 t6 aluminum makes it suitable for use in any environment, whether it be in water or air.

6061 t6 is a general purpose alloy that has excellent corrosion resistance, good weldability and is quite strong. It also has good machinability and can be easily worked by hand tools.

For more details about 6061 aluminum sheet.

6061 aluminum sheet plate

Aluminum 6061 t6 properties

Aluminum 6061 t6 is the most widely used aluminum alloy because it has the best combination of strength to weight ratio, corrosion resistance, and weldability.

Data points with the AA note have been provided by the Aluminum Association, Inc. and are NOT FOR DESIGN.

| Physical Properties | Metric | English | Comments |

| Density | 2.7 g/cc | 0.0975 lb/in³ | AA; Typical |

| Hardness, Brinell | 95 | 95 | AA; Typical; 500 g load; 10 mm ball |

| Hardness, Knoop | 120 | 120 | Converted from Brinell Hardness Value |

| Hardness, Rockwell A | 40 | 40 | Converted from Brinell Hardness Value |

| Hardness, Rockwell B | 60 | 60 | Converted from Brinell Hardness Value |

| Hardness, Vickers | 107 | 107 | Converted from Brinell Hardness Value |

| Ultimate Tensile Strength | 310 MPa | 45000 psi | AA; Typical |

| Tensile Yield Strength | 276 MPa | 40000 psi | AA; Typical |

| Elongation at Break | 12 % | 12 % | AA; Typical; 1/16 in. (1.6 mm) Thickness |

| Elongation at Break | 17 % | 17 % | AA; Typical; 1/2 in. (12.7 mm) Diameter |

| Modulus of Elasticity | 68.9 GPa | 10000 ksi | AA; Typical; Average of tension and compression. Compression modulus is about 2% greater than tensile modulus. |

| Notched Tensile Strength | 324 MPa | 47000 psi | 2.5 cm width x 0.16 cm thick side-notched specimen, Kt = 17. |

| Ultimate Bearing Strength | 607 MPa | 88000 psi | Edge distance/pin diameter = 2.0 |

| Bearing Yield Strength | 386 MPa | 56000 psi | Edge distance/pin diameter = 2.0 |

| Poisson’s Ratio | 0.33 | 0.33 | Estimated from trends in similar Al alloys. |

| Fatigue Strength | 96.5 MPa | 14000 psi | AA; 500,000,000 cycles completely reversed stress; RR Moore machine/specimen |

| Fracture Toughness | 29 MPa-m½ | 26.4 ksi-in½ | KIC; TL orientation. |

| Machinability | 50 % | 50 % | 0-100 Scale of Aluminum Alloys |

| Shear Modulus | 26 GPa | 3770 ksi | Estimated from similar Al alloys. |

| Shear Strength | 207 MPa | 30000 psi | AA; Typical |

| Electrical Resistivity | 3.99e-006 ohm-cm | 3.99e-006 ohm-cm | AA; Typical at 68°F |

| CTE, linear 68°F | 23.6 µm/m-°C | 13.1 µin/in-°F | AA; Typical; Average over 68-212°F range. |

| CTE, linear 250°C | 25.2 µm/m-°C | 14 µin/in-°F | Estimated from trends in similar Al alloys. 20-300°C. |

| Specific Heat Capacity | 0.896 J/g-°C | 0.214 BTU/lb-°F | |

| Thermal Conductivity | 167 W/m-K | 1160 BTU-in/hr-ft²-°F | AA; Typical at 77°F |

| Melting Point | 582 – 652 °C | 1080 – 1205 °F | AA; Typical range based on typical composition for wrought products 1/4 inch thickness or greater; Eutectic melting can be completely eliminated by homogenization. |

| Solidus | 582 °C | 1080 °F | AA; Typical |

| Liquidus | 652 °C | 1205 °F | AA; Typical |

| Solution Temperature | 529 °C | 985 °F | |

| Aging Temperature | 160 °C | 320 °F | Rolled or drawn products; hold at temperature for 18 hr |

| Aging Temperature | 177 °C | 350 °F | Extrusions or forgings; hold at temperature for 8 hr |

The advantages of 6061-T6 Aluminum Plate

- Aluminum 6061-T6 is artificially aged.

- 6061-T6 has a higher tensile and yield strength than 6061-T4.

- Offers good finishing characteristics.

- Can be welded or joined.

- Can also be anodized.

6061-T6 Aluminum Sheet Applications

Common applications for 6061-T6 aluminum sheet include:

- Aircraft fittings

- camera lens mounts

- couplings, marines fittings and hardware

- electrical fittings and connectors

- decorative or misc

- hardware

- hinge pins

- magneto parts

- brake pistons

- hydraulic pistons

- appliance fittings

- valves and valve parts

- bike frames.

6000 series aluminum

In addition to the main aluminum, the two most important metal elements in the 6000 series aluminum alloy are silicon and magnesium, so the 6000 series aluminum alloy is also called aluminum magnesium silicon alloy.

6000 series aluminum alloys commonly used in industry are

6061 aluminum sheet

6063 aluminum sheet

6082 aluminum sheet

Yield strength of aluminum 6061 T6

6061-T6. T6 temper 6061 has an ultimate tensile strength of at least 42,000 psi (290 MPa) and yield strength of at least 35,000 psi (241 MPa). In thicknesses of 0.250 inch (6.35 mm) or less, it has elongation of 8% or more; in thicker sections, it has elongation of 10%.

6061 aluminum vs 7075

6061 aluminum is a general purpose, low cost alloy that can be easily machined to tight tolerances. It offers good corrosion resistance and weldability. The magnesium content makes it a valuable choice for parts requiring a formable product.

7075 aluminum has a high strength-to-weight ratio and superior corrosion resistance because of its alloy content. The titanium and copper make it even stronger and more resistant to heat than the 6061 aluminum, but engineering properties are not as good because it cannot be easily machined to tight tolerances.

7075 Aluminum has higher strength and lower weight than 6061 aluminum but has lower hardness.

6061 aluminum VS 6063

Both 6061 and 6063 are made up of magnesium and silicon as their primary alloying elements, meaning they exhibit many of the same properties.

6063 is a common grade used for custom extrusions. 6061 features higher strength (tensile strength range is 20 to 42 KSI) than 6063.

For more related reading, refer to the following articles

5083 aluminum alloy sheet VS. 6061 aluminum metal sheets